The human factor or how the Fork saved 500 devices that detect cancer

In this article, we will talk about how we saved devices from being thrown into the trash with the help of a test stand on the Fork.

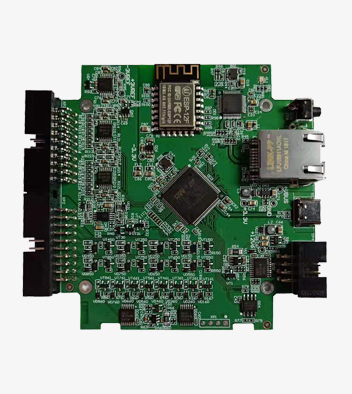

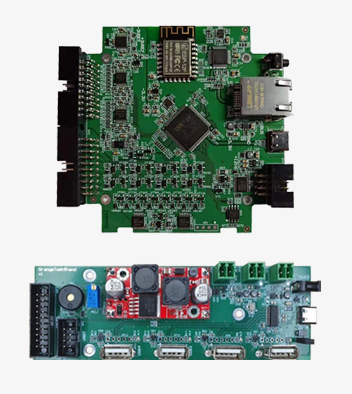

We are developing devices that can detect cancer in the early stages and in January 2021 launched NOTA-personal mole trackers that detect melanoma. In particular, we started testing PCBa NOTA on a functional stand created on the basis of Fork and Puh.

During testing, we found a strange thing: the test that checks Bluetooth shows an error on all boards. For us, it looks like this:

During testing, we found a strange thing: the test that checks Bluetooth shows an error on all boards. For us, it looks like this:

An erroneous test is highlighted in red

Note that production and testing is carried out in China. And we see this information in our office on the other side of the Earth, through our server.

(A bit of advertising: This is easy to do on a Fork, and when you buy a board, we will help you set up such a server).

We begin to deal with manufacturers and…

(A bit of advertising: This is easy to do on a Fork, and when you buy a board, we will help you set up such a server).

We begin to deal with manufacturers and…

here you need to go back to December 2020

Before starting any production, you need to send the manufacturer a specification that describes what and where to solder, so that everything works according to the author's idea. We have a special chip-antenna in the specification on the NOTA board, through which Bluetooth transmits the mole survey data to the app on the phone. And just before the launch, it turns out that manufacturers can't get a chip-antenna. We have provided for this problem in advance, so the board has the ability to use not the chip-antenna, but the antenna that is divorced on the board. It has modest characteristics, but they are quite enough to transmit NOTA measurements, since the device does not require a long distance to work.

We made a new documentation where the resistor is soldered differently so that the antenna divorced on the board works, and sent the documentation to production.

But then the human factor intervened: manufacturers used the first version of the specification. It is quite difficult to remotely control what documentation is used. Everything is built on trust: if the manager said that he will send a new specification for production, then we can only hope that the information will really reach.

We made a new documentation where the resistor is soldered differently so that the antenna divorced on the board works, and sent the documentation to production.

But then the human factor intervened: manufacturers used the first version of the specification. It is quite difficult to remotely control what documentation is used. Everything is built on trust: if the manager said that he will send a new specification for production, then we can only hope that the information will really reach.

Back to 2021

...and, as a result, 500 boards were soldered according to the old specification.

Since there is no chip antenna, and the resistor is selected as if it is, and the Bluetooth, respectively, did not work. And the functional stand on the Fork revealed this.

Now our Chinese friends will simply solder the resistors. But that's another story!

P.S. A nice bonus from the server is that we can see online how testing is going, whether it is going at all and how many boards were tested per day. Agree, this is important when the production is thousands of kilometers away from the development engineers!

Now our Chinese friends will simply solder the resistors. But that's another story!

P.S. A nice bonus from the server is that we can see online how testing is going, whether it is going at all and how many boards were tested per day. Agree, this is important when the production is thousands of kilometers away from the development engineers!

Assemble your test stand

Below you can order the key components of our stand at a favorable price and assemble your assistant for automated testing.

Orange stand

Pogo-pin

for 100 pieces

FORK

PowerUSBhub

FORK + PowerUSBhub

Engineers from these countries work with the Fork

PRODUCT Guide

Subscribe news

Privacy policy

This privacy policy describes how and when we collect, use, and share information when you provide your personal information(name, phone number, email address) on the site forktestlab.com or related sites and services.

This privacy policy does not apply to the actions of third parties that we do not own or control. You can refer to Artes Electronics privacy policy to learn more about its privacy practices.

__________

Information we collect

In order to complete your order or contact you to discuss a partnership, you must provide us with certain information, such as your name, email address, phone number(in some cases, postal address, payment information, and details of the product you are ordering). You can also provide us with additional personal information (for example, for an individual order) if you contact us directly.

__________

Why we need your information and how we use it

We rely on a number of legal grounds to collect, use, and share your information, including:

as necessary to provide our services, such as when we use your information to fulfill your order, resolve disputes, or provide customer support;

when you have given your affirmative consent, which you can revoke at any time, for example by subscribing to our mailing list.

__________

Information sharing and disclosure

Information about our customers is important to our business, so we do not share this information with third parties. Otherwise, it is possible only after receiving your personal consent.

__________

Data storage

We only store your personal information for as long as it is necessary to provide our services and as described in this privacy policy. However, we may also be required to store this information in accordance with our legal and regulatory obligations, resolve disputes, and enforce our agreements. Maximum period of storage of your data: 5 years.

__________

Transfer of personal information outside the EU

We may store and process your information through third-party hosting services in the United States and other jurisdictions. As a result, we may transfer your personal information to a jurisdiction with different data protection and government oversight laws than your jurisdiction. If we are deemed to be transferring information about you outside the EU, we rely on Privacy Shield as the legal basis for the transfer.

__________

Your right

If you live in certain territories, including the EU, you have a number of rights with respect to your personal information. While some of these rights apply in General, some rights only apply in certain limited cases. We describe these rights below:

Access. You may have the right to access and obtain a copy of the personal information we hold about you by contacting us using the contact information below.

Edit, restrict, delete. You also have the right to change, restrict or delete your personal information. No exceptional circumstances (for example, when we are required to store data for legal reasons) We will generally delete your personal information upon request.

An object. You may object to the processing of some of your data based on our legitimate interests and the receipt of marketing messages from us after you have provided your explicit consent to receive them(providing mail is such consent). In such cases, we will delete your personal information if we do not have a valid and legitimate reason to continue using this information or if it is necessary for legal reasons.

__________

How to contact us

For the purposes of EU data protection law, we, Artes Electronics, are the data controller of your personal information. If you have any questions or concerns, you can contact us at info@arteselectronics.com. In addition, you can send us an mail at: office 17, 50A Tambovskaya str., Saint Petersburg, 192007, Russia

This privacy policy does not apply to the actions of third parties that we do not own or control. You can refer to Artes Electronics privacy policy to learn more about its privacy practices.

__________

Information we collect

In order to complete your order or contact you to discuss a partnership, you must provide us with certain information, such as your name, email address, phone number(in some cases, postal address, payment information, and details of the product you are ordering). You can also provide us with additional personal information (for example, for an individual order) if you contact us directly.

__________

Why we need your information and how we use it

We rely on a number of legal grounds to collect, use, and share your information, including:

as necessary to provide our services, such as when we use your information to fulfill your order, resolve disputes, or provide customer support;

when you have given your affirmative consent, which you can revoke at any time, for example by subscribing to our mailing list.

__________

Information sharing and disclosure

Information about our customers is important to our business, so we do not share this information with third parties. Otherwise, it is possible only after receiving your personal consent.

__________

Data storage

We only store your personal information for as long as it is necessary to provide our services and as described in this privacy policy. However, we may also be required to store this information in accordance with our legal and regulatory obligations, resolve disputes, and enforce our agreements. Maximum period of storage of your data: 5 years.

__________

Transfer of personal information outside the EU

We may store and process your information through third-party hosting services in the United States and other jurisdictions. As a result, we may transfer your personal information to a jurisdiction with different data protection and government oversight laws than your jurisdiction. If we are deemed to be transferring information about you outside the EU, we rely on Privacy Shield as the legal basis for the transfer.

__________

Your right

If you live in certain territories, including the EU, you have a number of rights with respect to your personal information. While some of these rights apply in General, some rights only apply in certain limited cases. We describe these rights below:

Access. You may have the right to access and obtain a copy of the personal information we hold about you by contacting us using the contact information below.

Edit, restrict, delete. You also have the right to change, restrict or delete your personal information. No exceptional circumstances (for example, when we are required to store data for legal reasons) We will generally delete your personal information upon request.

An object. You may object to the processing of some of your data based on our legitimate interests and the receipt of marketing messages from us after you have provided your explicit consent to receive them(providing mail is such consent). In such cases, we will delete your personal information if we do not have a valid and legitimate reason to continue using this information or if it is necessary for legal reasons.

__________

How to contact us

For the purposes of EU data protection law, we, Artes Electronics, are the data controller of your personal information. If you have any questions or concerns, you can contact us at info@arteselectronics.com. In addition, you can send us an mail at: office 17, 50A Tambovskaya str., Saint Petersburg, 192007, Russia